SERMA Activities

ESD Activities

Definitions:

- ESD : ElectroStatic Discharge

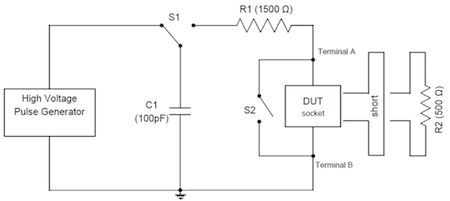

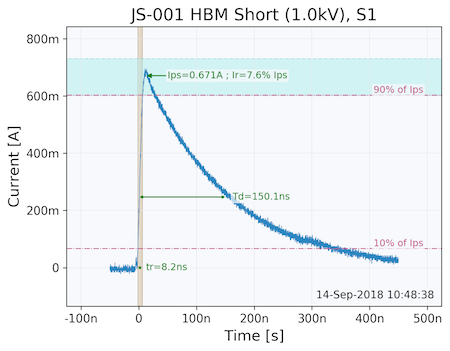

- HBM : (Human Body Model) An electrostatic discharge(ESD) event meeting the waveform criteria specified in standards, approximating the discharge from the fingertip of a typical human being to a grounded device

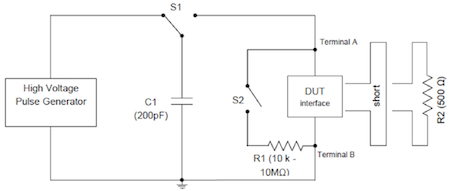

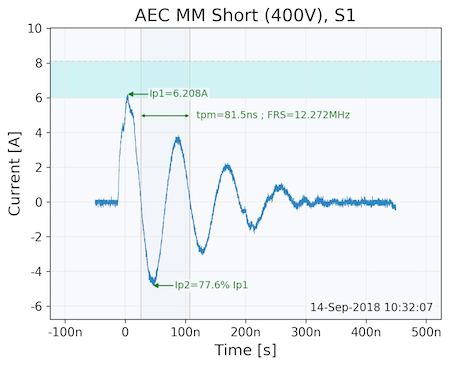

- MM : (Machine Model) An electrostatic discharge (ESD) used to simulate an event occurring from a low resistance source

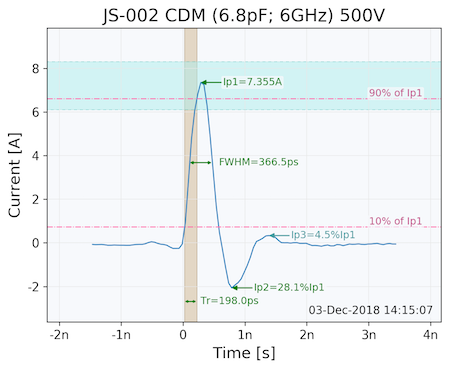

- CDM : (Charge Device Model) An electrostatic discharge (ESD) used to simulate the actual discharge event that occurs when a charged device is quickly discharged to another object at a lower electrostatic potential through a single pin or terminal

- EPA : ESD Protected Areas

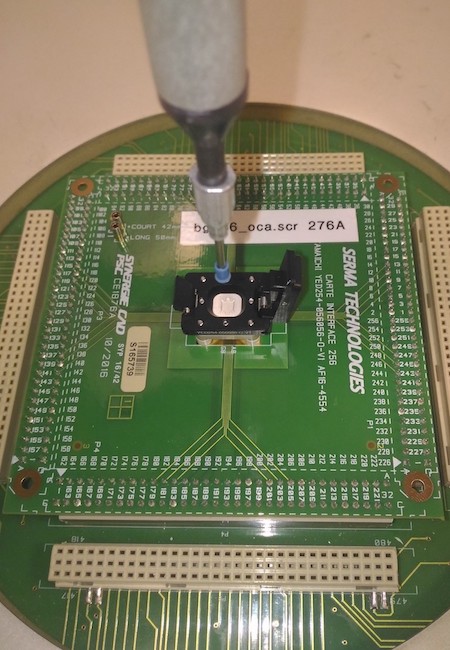

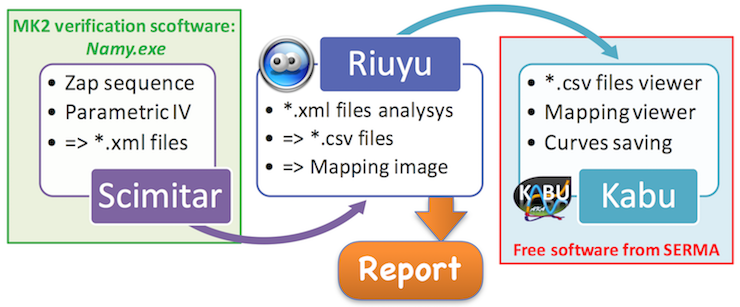

- ESD tester : Equipment that applies a HBM ESD (Thermo Keytek Zapmaster MK.2 SE) or a CDM ESD (Thermo Scientific Orion3) to a component

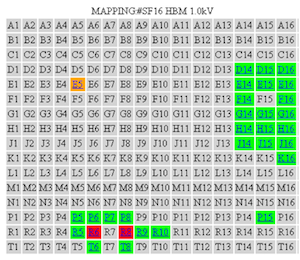

| Human Body Model (HBM) & Machine Model (MM) | ||

|

SERMA Main Strength on HBM & MM tests

|

|

Human Body Model (HBM) Human Body Model (HBM) |

Systems Strengths ?

Model ?

|

|

| Charged Device Model (CDM) | ||

|

SERMA Main Strength on CDM tests

|

|

|

Model ?

|

|

| Additionnal information | ||

|

|

|

|

|

|

Serma Technologies : BHT - Bâtiment 52 - 7, Parvis Louis Néel – CS20050 - 38040 Grenoble – France

Customer Service: csc@serma.com ; +33 (0)5 57 26 08 88

LU Activities

Definitions:

- ESD : ElectroStatic Discharge

- LU : (Latch-Up) A state in which a low-impedance path, resulting from an overstress that triggers a parasitic thyristor structure, persists after removal or cessation of the triggering condition

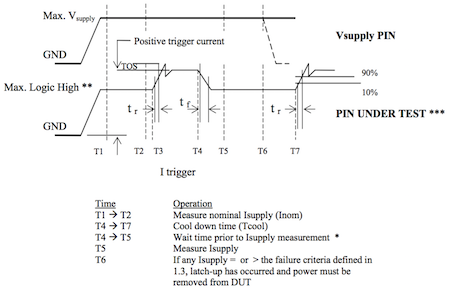

- Vsupply overvoltage test: A latch-up test that supplies overvoltage pulses to the Vsupply pin (or pin group) under test

- Latch-up tester : Test equipment capable of performing the tests as specified in standards. For devices requiring dynamic testing, required timing signals and logic vectors may be applied by the latch-up tester itself, external equipment, and/or external components as appropriate

- Heat source : Equipment capable of heating and maintaining the DUT at the maximum operating temperature specified in the device specification during the latch-up test

- EPA : ESD Protected Areas

| Latch-up (LU) Tests | ||

|

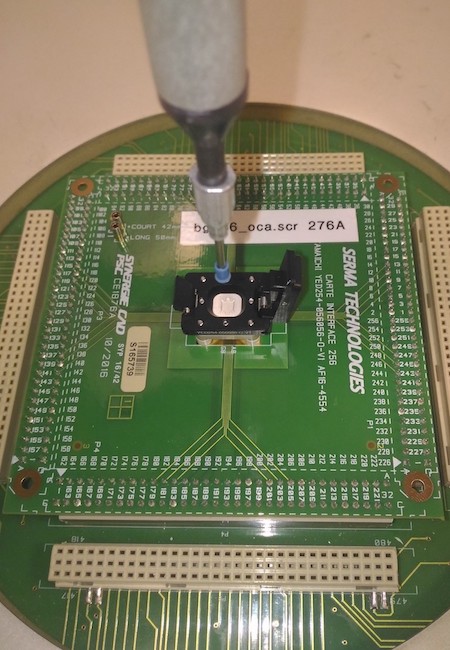

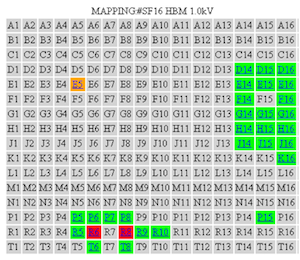

SERMA Main Strength

|

|

|

Test Description

|

|

|

|

Systems Strengths ?

|

How ?

|

| Additionnal information | ||

|

|

|

![]()

Serma Technologies : BHT - Bâtiment 52 - 7, Parvis Louis Néel – CS20050 - 38040 Grenoble – France

Customer Service: csc@serma.com ; +33 (0)5 57 26 08 88

FIB Edit Activities

Definitions :

- FIB : Focused Ion Beam

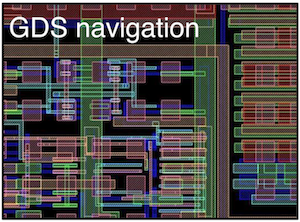

- GDS : (Graphic Database System) Files used in the FIB equipment to navigate to a specific area in the integreted circuit

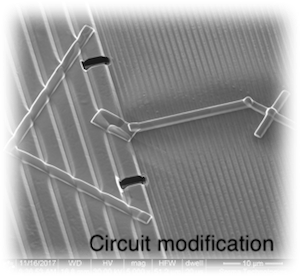

- Circuit Edit : Technique used in new design flow modifications on integreted circuit; This technique can be applied to design optimization changes before final productionin, debugging process or solutions fixes

|

SERMA Main Strength

|

|

|

Systems Strengths ?

|

|

Chemistries available ?

|

|

How ?

|

|

Main uses ?

|

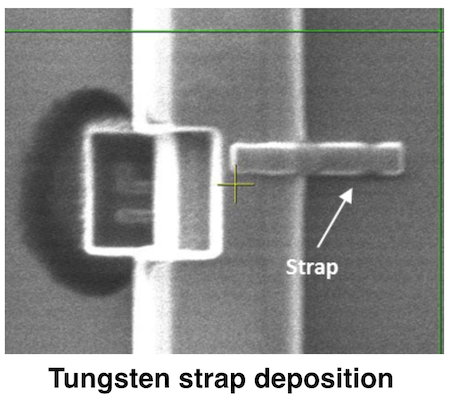

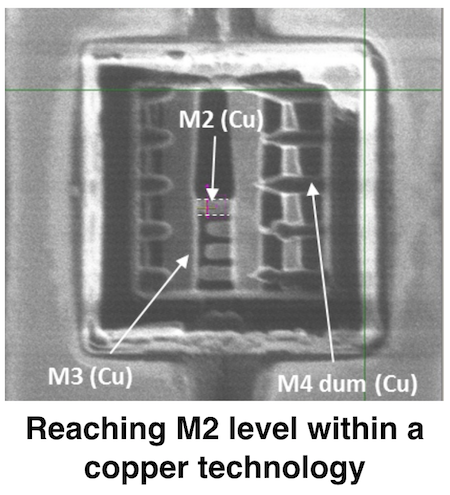

| Circuit-Edit examples | ||

|

|

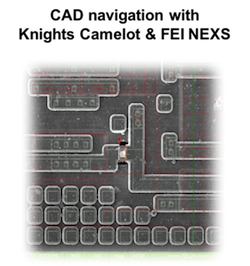

Using GDS files for navigation |

|

![]() Serma Technologies : BHT - Bâtiment 52 - 7, Parvis Louis Néel – CS20050 - 38040 Grenoble – France

Serma Technologies : BHT - Bâtiment 52 - 7, Parvis Louis Néel – CS20050 - 38040 Grenoble – France

Customer Service: csc@serma.com ; +33 (0)5 57 26 08 88

Machine Model (MM)

Machine Model (MM)